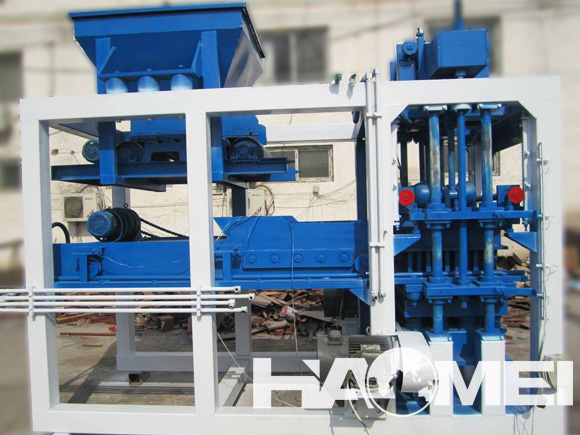

QT8-15 Brick Making Machine

CATEGORY AND TAGS:Brick Making Machine qt 8-15 bricks machine, qt8-15 block machine, qt8-15 block making machine, qt8-15 brick making machine

Dimension:6800×3800×2660(mm)

Pallet Size:850×850×20(PVC plate)

Weight:9100kg

Vibration Frequency:50-90Hz

Maximum Excitation Force:80KN

Molding Cycle:15-20S

Installed Capacity:31.7KW

- Specifications

- Product Features

- Advantages of Haomei

Haomei QT8-15 brick making machine has excellent industrial technical design, great appearance, adopt our many years of market experience. Users of QT8-15 block making machine are free to select which stage of manufacturing processes needs to be automated. Of course you can always set the machine to fully automatic mode if it fits the situation.

Technical Specifications of QT8-15 Block Making Machine:

| Dimension | 6800x2090x3000mm |

| Rating pressure | 21MPa |

| Vibration | Table vibration |

| Vibration frequency | 2800 – 4500r/min |

| Pallet size | 1100x680mm |

| Cycle time | 12-25sec. |

| Power | 43.88kW |

| Weight | 9840kg |

Theoretical yield table of QT8-15 Brick Making Machine

| Brick Specifications | Samples | pcs/mold | pcs/h | pcs/8h | 1 year (300 days) |

| Blocks pcs 390×190×190mm 71pcs/m3 |

|

8 | 1440 | 11520 | 48676m3 |

| Blocks pcs 390×100×190mm 135pcs/m3 |

|

14 | 2520 | 20160 | 44800m3 |

| Dutch Bricks 200×100×60mm 50pcs/m2 |

|

21 | 3780 | 30240 | 181440m2 |

| Dog-Bone Bricks 200×165×60mm 30pcs/m2 |

|

12 | 2160 | 17280 | 171089m2 |

| Zigzag Bricks 225×112.5×60mm 40pcs/m2 |

|

20 | 3600 | 28800 | 218734m2 |

| Perforated Bricks 240x115x90 402pcs/m3 |

|

18 | 3240 | 25920 | 7.77 millionpcs |

| Solid Bricks 240x115x53 683pcs/m3 |

|

36 | 6480 | 51840 | 15.55 millionpcs |

1. Unique material storage and batching system ensures accurate feeding of concrete mix and avoids material segregation caused by internal stress or external forces. It also serves as a guarantee that the resultant blocks have a uniform thickness.

2. Multi-source vibration system is exclusively designed for a heavy-duty concrete block machine. It is especially suitable for use on a large-scale worktable. True to its name, this vibration system provides multiple sources of vibration and brings together computer control, hydraulic drive, and motor synchronization technologies into one unit.

Both vibration frequency and amplitude are adjustable to specific manufacturing process. Generally speaking, a low-frequency vibration would be used when material is fed into the mold while a high-frequency one would be employed during the block pressing process. The vibration excitation force would also be different according to the variety of material to be processed.

3. The combination of digital sensor and displacement sensor allows each movement to be controlled precisely. For those with busy block making tasks, this sensor design might be your best bet as it incorporates hundreds of manufacturing processes for users to choose from.

4. Machine fault diagnosis is done automatically. Once a fault is identified, the alarm would automatically go off to remind operators of the abnormality.

5. The automatic block making machine can be connected to a remote control system which facilitates monitoring and fault diagnosis from a distance.

1. Super-strong steel structure, made of extensive imported original parts, ensuring more stability and reliability for the main machine body.

2. The whole process uses a PLC aptitude control and dialogue system of human-machine interface, easy to analyze the chance signal, ensure the best operation effect.

3. High-efficient and super-strong vibration system, computer-control flow pressure of the hydraulic system, realize vertically synchronous vibration, frequency conversion, and braking, with synthetic output compounded with double vibration sources, thus greatly increase product compactness and mold-box service life.

4. The cloth system adopts semi-closed screen reticular rotational feeding unit to feed materials forcedly, with evenness and even speed, ensuring product intensity.

5. Fitted with special hydraulic loading unit, readily realize mass and automatic production, saving a great deal of human power, maintenance field, and circulating fund investment.