Categories

- Case & News (49)

- Blog (515)

Horizontal double shaft mixer is a kind of equipment commonly used in concrete production, which is widely welcomed for its high efficient mixing performance and good mixing uniformity. Horizontal double shaft mixer is widely used in concrete mixing plant, precast plant, mortar production line and other fields, which is an indispensable and important equipment in modern concrete production. With its high efficiency, uniformity and durability, horizontal double-shaft mixer has become one of the important equipments in concrete production.

Horizontal double shaft mixer has various models, mainly based on the different mixing capacity to distinguish, common models are JS500, JS750, JS1000, etc., where the number represents the discharge capacity of the mixer (in liters). Different models are suitable for different output requirements.

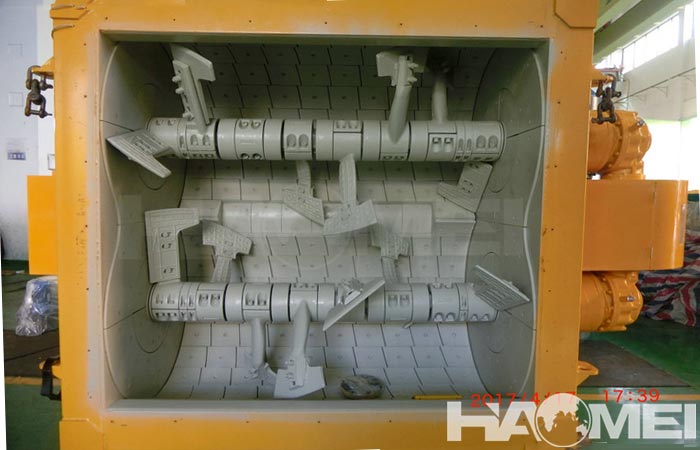

Horizontal double shaft mixer is mainly composed of the following parts:

– Mixing cylinder: usually a horizontal cylindrical structure for holding the mixing materials.

– double-shaft mixing device: It contains two parallel mounted mixing shafts, each of which is equipped with a specific shape of mixing blades.

– Discharge port: located at one end of the mixing cylinder, used to discharge the stirred material.

– Driving system: including motor, reducer, etc., used to drive the rotation of the mixing shaft.

– Bracket and base: used to support the whole mixer and ensure its stability.

– Control system: used to control the speed, time and other parameters in the mixing process.

Working Principle of double shaft horizontal miser:

When the double shaft mixer starts, the two mixing shafts rotate according to the set direction and speed, driving the mixing blades to stir the materials in the cylinder. Through the interaction of the two mixing shafts in opposite directions, the materials can form convection in the cylinder, thus realizing the mixing between the materials. Due to the design of double shafts, the materials can be mixed more fully in the cylinder to ensure the quality of the final product.

Difference with single shaft mixer:

– Mixing effect: twin shaft concrete mixer has two mixing shafts, so the mixing is more uniform, suitable for products that need high quality mixing.

– Production capacity: double shaft mixers are generally more efficient than single-shaft mixers, and are more suitable for mass production occasions.

– Applicable materials: twin shaft mixers have better adaptability to materials with higher viscosity or containing large particles.

Horizontal double shaft mixers are suitable for a variety of occasions, including but not limited to:

– Large-scale construction projects: such as highways, bridges, airports and other infrastructure construction.

– Commodity concrete production: specifically for the production of commercial concrete for sale.

– Precast factory: for the production of precast concrete components.

– Special concrete mixing: such as dry mortar, colored concrete and other special purpose concrete production.

To summarize, horizontal double shaft mixer has an important application value in the field of concrete production and building construction due to its high efficient mixing capacity and wide applicability.