Mobile Asphalt Mixing Plant

CATEGORY AND TAGS:Asphalt Mixing Plant mobile asphalt mixing plant

■ Condition: Brand new

■ Minimum Order Quantity: One set

■ Delivery port: Qingdao or Tianjin port, China

■ Payment term: L/C, T/T

■ Guarantee period: 12 months

■ Delivery time: 10-15 days after received deposit

■ Installation time: 20days

- Specifications

The Features of Mobile Asphalt Mixing Plant:

1. Integrated design of batch type drying drum and mixing drum reduce investment cost for customer;

2. Simple structure, easy to handle: drying while drum rotates in the counter-clockwise direction (from burner), discharging while drum rotates in the clockwise direction (from burner), and the wind is swirled in the center of the drum;

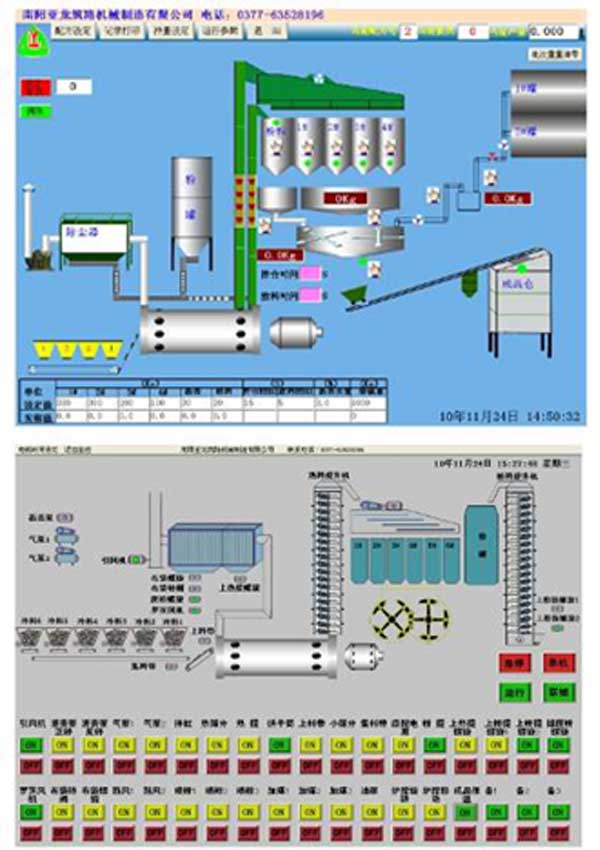

3. PLC control, touch screen with free auto/manual transfer are available for this kind of concrete mixing equipment.

4. Movable chassis structure allows a fast as well as easy transport and installation.

5. Coal and oil burner are available upon customer’s request.

Asphalt mixture control system:

Strong-current cabinet:

1 Adopt the GGD cabinet conforming to the national standard

2 Source electric control units from Siemens

3 Orderly wiring, clear markers and convenient overhaul

Environmental dust removal system

1 The bag filter from DuPont: NOMEX needled felt

2 Electronic pulse structure

3 Emission concentration of dust less than 50mg/Nm3

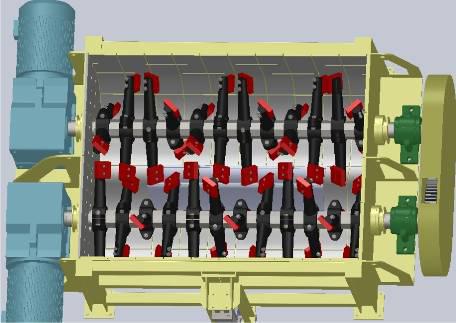

Dual-motor driven agitator:

1 Wear resistance blade

2 A synchromesh gear

3 Horizontal Double-shaft

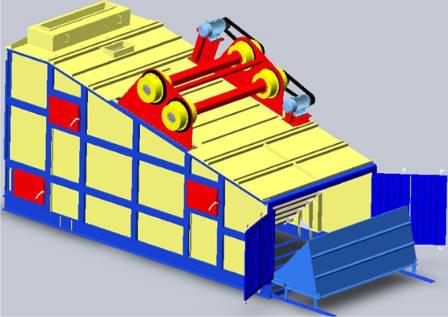

High-efficiency vibration screen

1 Driven by dual motors

2 Convenient maintenance

3 Vibrating shaft installed outside the housing of the vibrating screen

4 Movable slide board

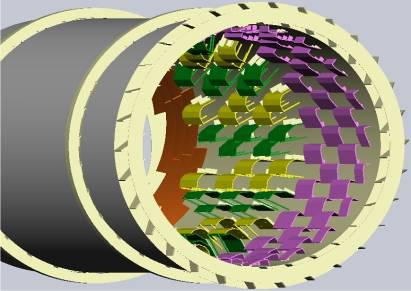

Newly-designed drying system

1 Specially designed blades

2 With an insulating layer

3 Direct-coupled gear reducer driving through crosshead universal joint

The Technical Parameters of Mobile Asphalt Mixing Plant:

| Type | LBY2000 | LBY1000 | |

| Production Capacity(t/h) | 160 | 80 | |

| Production Capacity(t/h) | 440 | 230 | |

| The Weighing Accuracy(%) | Aggregate | +0.5 | +0.5 |

| Powder | +0.25 | +0.25 | |

| Bitumen | +0.20 | +0.20 | |

| Way of dust filter | Bag dust filter | Bag dust filter | |

| Dust emission | ≤100 | ≤100 | |

| Storage Bin Type | Side-type | Side-type | |

| The Volume Of Storage Bin(T) | 100 | 60 | |

Settlement and Transport Plans