Categories

- Case & News (48)

- Blog (515)

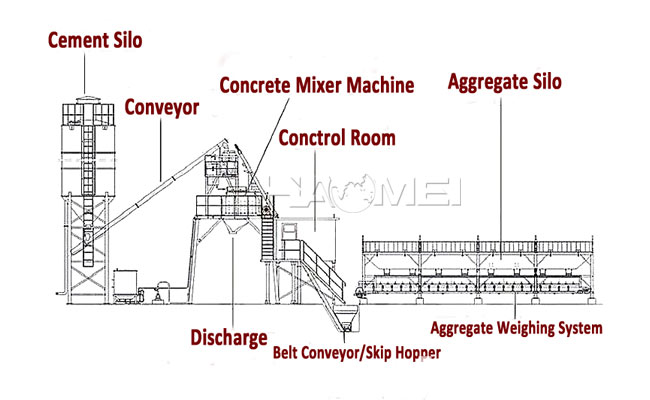

A concrete batching plant is a facility used to produce ready-mixed concrete and usually consists of several parts, each with a specific function.

Following are the major components of a concrete batching plant and their detailed descriptions:

1. Raw material storage system:

– Aggregate storage silo: Used for storing aggregates such as sand, stone, etc. Usually there are several sub-bins so that they can be accessed on demand.

– Water Tank: Used to store water for concrete production.

– Cement silo: Used for storing cement, usually a large cylindrical or square storage facility.

– Impregnant storage device: Used to store all kinds of admixtures, such as water reducing agent, air-entraining agent, etc., usually small tanks or barrels.

2. Weighing system:

– Weighing Hopper: Used to accurately weigh various raw materials (e.g. water, aggregate, cement and admixtures) to ensure the accuracy of concrete proportioning.

– Electronic weighing device: automatic weighing is realized by electronic sensor to improve weighing accuracy and efficiency.

3. Mixing system:

– Mixer: it is the core part of concrete batching plant, responsible for mixing various raw materials into uniform concrete. According to the type, the concrete mixer can be forced mixer or planetary mixer.

– Mixing arms and blades: inside the mixer, used to enhance the mixing effect.

4. Control system:

– Automatic control system: to realize automatic control of the whole mixing plant through computer program, including weighing of raw materials, mixing time, discharging and so on.

– Monitoring system: It is used to monitor the production process in real time to ensure that the parameters are within the set range.

5. Discharge system:

– Discharge hopper: after the concrete mixing is completed, the concrete will be sent out through the discharge hopper, which is usually equipped with electric or pneumatic devices.

– Conveying system: Conveying concrete to the construction site, commonly used methods include concrete pumps, conveyor belts and so on.

6. Auxiliary equipment:

– Cleaning system: used to clean the mixer and other equipment to ensure the normal operation of the equipment and the quality of concrete.

– Generator: Provide backup power when needed to ensure that the mixing plant can still operate in case of power failure.

7. Environmental protection facilities:

– Dust removal system: control dust emission during the production process to protect the environment and workers’ health.

– Wastewater treatment system: to treat the wastewater produced in the production process, in line with environmental protection requirements.

The above are the main components of the concrete batching plant, and all parts work together to ensure efficient production and quality control of concrete.