Categories

- Case & News (50)

- Blog (571)

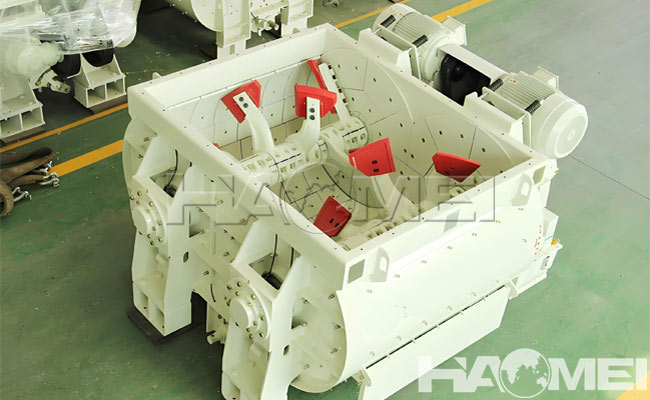

Twin shaft concrete mixer is a common construction machinery and equipment, widely used in a variety of large-scale engineering projects, its design is to ensure that the mixer can be one of the keys to normal operation.

The following is a detailed introduction to the design of twin shaft concrete mixer:

1. Overall structure

The twin-shaft concrete mixer is mainly composed of transmission system, mixing system, hydraulic system (if any) and frame.

– Transmission system: it includes electric motor, reducer, gears and bearings and other parts. The electric motor provides power, the reducer is used to reduce the speed and increase the torque, and the gears and bearings are used to transfer the power and ensure the normal rotation of the mixing cylinder.

– Mixing system: It mainly consists of mixing cylinder, mixing blades (or paddles), feeding port and discharging port. The mixing cylinder is the main component to hold the concrete raw material and mix it, while the mixing blade shears, impacts and mixes the raw material through rotation.

– Hydraulic system (if any): It is mainly used to control the opening and closing of the feeding port, discharging port and the tilting angle of the mixing cylinder.

2. Design details

(1)Transmission system design

– Selection of electric motor: according to the production capacity of the concrete mixer and the working environment and other factors for comprehensive consideration, select the appropriate type and power of the electric motor.

– Reducer selection: Considering the reduction ratio and torque size and other factors, select the reducer that can meet the working requirements of the concrete mixer.

– Gear and bearing design: Ensure the strength and durability of gears and bearings to meet the needs of long-term operation of the mixer.

(2)Mixing system design

– Mixing drum volume: Determine the volume of the mixing drum according to the production demand to ensure that it can hold enough concrete raw materials.

– Design of mixing blades: The number, shape and arrangement of mixing blades have an important influence on the mixing effect. The number of blades should be moderate, and the shape and arrangement should be able to ensure that the concrete raw materials are fully mixed in the mixing cylinder.

– Design of feeding and discharging ports: The feeding port should be convenient for the addition of raw materials, and the discharging port should be convenient for the discharge of concrete. At the same time, the sealing of the feeding and discharging ports should be ensured to prevent concrete leakage.

(3)Hydraulic system design (if any)

– Flow and pressure design: Determine the flow and pressure of the hydraulic system according to the production demand to ensure that it can control the tilting angle of the mixing drum and the opening and closing of the feeding and discharging ports.

– Control mode design: the control mode of the hydraulic system should be flexible and convenient for the operator to control and adjust the mixer.

3. Design Considerations

– Material strength and durability: the concrete mixer will be subjected to greater force and wear in the working process, so the mixer should be selected from high-strength and durable materials to manufacture various components.

– Convenience of repair and maintenance: the design should take into account the concrete mixer’s repair and maintenance needs, to ensure that the components are easy to disassemble and replace.

– Transportation and installation: the design should take into account the transportation and installation needs of the mixer to ensure that the concrete mixer can be easily transported to the site and installed and used.

4. Design Optimization

– Improvement of mixing efficiency: The mixing efficiency of the concrete mixer can be improved by optimizing the shape, number and arrangement of mixing blades, and adjusting the rotational speed and tilting angle of the mixing drum and other parameters.

– Energy consumption reduction: through optimizing the design of transmission system and hydraulic system, as well as adopting energy-saving motor and reducer and other components, the energy consumption of the concrete mixer can be reduced.

– Intelligent control: the introduction of intelligent control system realizes remote monitoring and control of the concrete mixer, and improves the automation level and production efficiency of the concrete mixer.

To summarize, the design of twin-shaft concrete mixer is a complex and detailed process, which needs to comprehensively consider several factors to ensure the performance and quality of the mixer. Through reasonable design and optimization, we can produce highly efficient, durable and intelligent twin-shaft concrete mixers to meet the production requirements of engineering projects.