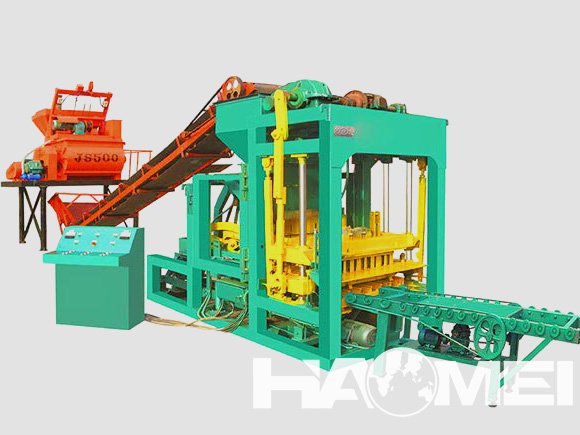

Fly Ash Bricks Machine

CATEGORY AND TAGS:Brick Making Machine fly ash brick making machine, fly ash brick plant, fly ash bricks machine, fly ash bricks machine price, fly ash bricks making machine cost

Model: QT series

Molding cycle: 15-20S

Capacity: 720-2160Pcs/Hr

Power: 20-48kw

- Specifications

- Models of Fly Ash Bricks Machine

- Capacity of Fly Ash Brick Plant

There are many core strengths of fly ash bricks machine for sale from Haomei. Based on those strengths, our fly ash brick making machine has longer service life and better performance. Fly ash bricks machine combines automatic and hydraulic skills that could manufacture good quality bricks taking fly ash, slag, concrete, concrete waste and mineral waste as raw materials. Meanwhile, the machine has the feature of advanced production technology, but also reuses fly ash to protect the environment, and it is very popular with customers.

Fly ash bricks making machine is very suitable to produce all kinds of hollow or solid brick, with all kinds of raw material: clay, shale, coal slack, fly ash etc. According to the mobility, it is divided into mobile and stationary machine; due to the different modes of operation, the machines can be distributed into full-automatic and semi-automatic machine; according to the molding structure, it can be divided into mechanical and hydraulic machine.

The progress of using fly ash brick making machine

1, Crushing and grinding lime stone

The raw materials of lime, gypsum and waste brick are broken by the jaw crusher and then go into the grinding head bin. The feeding machine at the bottom of the silo uniformly feeds the ball mill powder into the qualified powder to the dosing section.

2, Stir ingredients

Fly ash, furnace slag (or sand) are transported into the hopper by the car from the boiler of power plan. And the slag powder is sent to the horizontal mixer with water to be mixed even mixture in proportion according to the requirements of the slag powder.

3, Eliminate aging

The once stirred ash and slag mixture will enter the digestion and aging bin in a certain order. After a certain digestion and aging time, the mixture can be fed to the wheel roller for activation.

4, Wheel mill activation

After digestion and aging, the mixture is sent to the grinding machine for grinding and stirring, so as to damage the surface of raw material particles and expose them to new surface. At the same time, the mixture is mixed with water to meet the forming requirements of automatic plant for fly ash brick manufacturing. The mixture can be sent to the molding section.

5, Pressing and forming

The mixed material after being activated by the wheel is sent to the storage bin of the automatic fly ash brick plant, which is then pressurized by the brick machine to form the required brick. The brick is automatically stowed by the machine on the autoclave according to a certain code method. When the stacking is full, the blanks are pushed into the statically stowed marshalling lane, waiting to enter the autoclave for steaming and raising.

Strengths of Fly Ash Brick Machine Of Haomei

1, Frame work structure of fly ash brick making machine design.

We have design fly ash brick making machine into frame work type of structure. It has compact structure that has advantages of steadiness, good ability extension.

2, Manufactured by High-quality manganese steel.

We adopt thick manganese steel to manufacture high-class quality interlocking block machine. Honestly to say, there are 3 kinds of steels manufacturing brick machines, which are ordinary steel, carbon constructional steel and manganese steel. And the price of manganese steel fly ash brick machines are most expensive, while ordinary steel brick machines are the cheapest. So, in some degree, fly ask bricks machine price is fluctuating with the price of steels.

3, Hydraulic transmission.

Hydraulic fly ash brick making machine from Haomei group has been applied the technology of hydraulic transmission. The structure of hydraulic system is simple and light. With the help of it, fly ash bricks machines could act more steady performance, easy to operate and achieve complicated automatic working circulation.

| Model | Dimensions | Weight | Molding cycle | Pallet size | Power | The highest frequency |

| QT3-15 | 4100×1600×3000mm | 4.5t | 15-20S | 730×580×30mm | 20kw | 4800-5100(r/min) |

| QT4-15 | 5420×1550×2940mm | 6.5t | 15-20S | 850×570×30mm | 20kw | 4800-5100(r/min) |

| QT6-15 | 6350×1680×2850mm | 8t | 15-20S | 850×700×25mm | 29kw | 4800-5100(r/min) |

| QT8-15 | 4750×2000×2950mm | 10t | 15-20S | 1080×700×25mm | 33.55kw | 4800-5100(r/min) |

| QT10-15 | 8200×2000×2950mm | 11t | 15-20S | 1150×840×40 | 36.55kw | 4800-5100(r/min) |

| QT12-15 | 8200×2300×3000 | 13t | 15-20S | 1310×840×40mm | 46kw | 4800-5100(r/min) |

| QT15-15 | 5700×2500×3400 | 16t | 15-20S | 1320×1100mm | 48kw | 4800-5100(r/min) |

| Theoretical yield table | |||||

| Model | Product name | Product specifications | Number per plate | Block/h | Block/8h |

| QT3-15 | block | 390×190×190 | 3 | 540 | 4320 |

| brick | 240×115×90 | 11 | 1980 | 15840 | |

| standard bricks | 240×115×53 | 22 | 3960 | 31680 | |

| QT4-15 | block | 390×190×190 | 4 | 720 | 5760 |

| brick | 240×115×90 | 12--14 | 2160--2520 | 17280--20160 | |

| standard bricks | 240×115×53 | 24--26 | 4320--4680 | 34560--37440 | |

| QT6-15 | block | 390×190×190 | 6 | 1400-1080 | 11520-8640 |

| brick | 240×115×90 | 15 | 3600-2700 | 28800-21600 | |

| standard bricks | 240×115×53 | 36 | 7920-5940 | 63360-47520 | |

| QT8-15 | block | 390×190×190 | 8 | 1920-1440 | 15360-11520 |

| brick | 240×115×90 | 22 | 5040-3780 | 40320-30240 | |

| standard bricks | 240×115×53 | 45 | 10080-7560 | 80640-60480 | |

| QT10-15 | block | 390×190×190 | 10 | 2400-1800 | 19200-14400 |

| brick | 240×115×90 | 27 | 5760-4320 | 46086-34560 | |

| standard bricks | 240×115×53 | 54 | 12240-9180 | 97920-73400 | |

| QT12-15 | block | 390×190×190 | 12 | 2160 | 17280 |

| brick | 240×115×90 | 30 | 7200 | 57600 | |

| standard bricks | 240×115×53 | 60 | 14400 | 115200 | |

| QT15-15 | block | 390×190×190 | 15 | 2700 | 21600 |

| brick | 240×115×90 | 40 | 9600 | 76800 | |

| standard bricks | 240×115×53 | 80 | 19200 | 153600 | |