Categories

- Case & News (49)

- Blog (518)

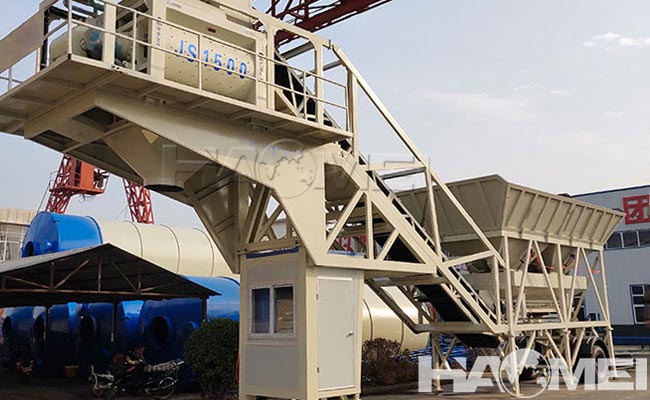

The mini portable concrete batch plant with productivity 25-50m3/h, which has the advantages of fast installation and easy transfer. The portable concrete batching plant have exactly the same operation process, operation method and maintenance as and the stationary concrete batch plant. At the same time, the mobile concrete batching plant has the unique characteristics of flexible movement, quick and easy disassembly and assembly, and simple storage management. Therefore, the portable concrete batch plant become the best and optimally equipped model in the mobile construction of ports, hydropower and other projects.

Except for external equipment such as screw conveyors and cement silos, all the wiring of the mini portable concrete batch plant does not need to be disassembled, and only a 30-ton crane is required to disassemble and shift in one day. During installation, if the ground is flat and solid, no foundation is needed, and production can be done on the same day, which is very suitable for units with tight schedules. The mobile concrete batching plant integrates a complete set of mixing plant equipment, and is equipped with walking wheels, which can be used for traction and transition by vehicles. This design is also suitable for construction sites with short construction periods and frequent transitions.

The mini portable concrete batch plant adopt fully automatic control system, that is, sand and gravel aggregate batching, weighing, conveying, mixing and unloading are all automatic operations, without manual intervention, manual only needs to click the start button before starting to punch. The automatic system of the portable concrete batching plant is easy to operate, high degree automation, integrated monitoring and remote operation, although the initial investment cost is relatively high, but it saves manpower, it is an ideal operating system for engineering roads and bridges and other ready mixing plants.