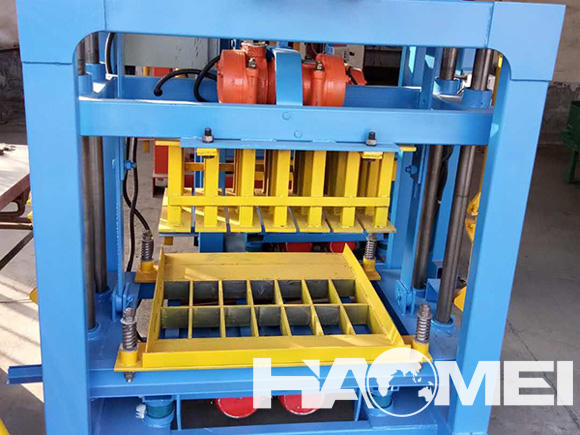

QT4-15 Brick Making Machine

CATEGORY AND TAGS:Brick Making Machine qt4-15 block machine, qt4-15 block making machine, qt4-15 brick making machine, qt4-15 bricks machine

Dimension:4850×4650×2250(mm)

Size of Pallet:850×550×16(PVC plate)

Weight:4000kg

Vibration Frequency:50-90Hz

Maximum Excitation Force:50KN

Molding Cycle:15-20S

Installed Capacity:21KW

- Specifications

- Main Features

- Haomei Strength

QT4-15 brick making machine is the most popular model in the block machine family because of its low price and high quality, the whole brick machine line is configurated with PLD1200 batching machine and JS500 concrete mixer.

Small model QT4-15 block making machine provides an intelligent operating platform that helps machine operators stay in total control. The brick machine works relatively fast, delivering high productivity. If you are in need of a high-efficiency brick making machine, please feel free to contact one of our technicians or sales representatives with your specific requirements.

The equipment structure is simple and practical, outlook is novel and attractive, in addition to produce permeable brick, it is particularly suited to the production of standard bricks, replacement of mold can produce many kinds of paving brick, hollow brick, curb stone etc.

Main Technical Parameters of QT4-15 Block Machine

| Raw Material | Sand, Cement, Fly Ash, Concrete, Boiler Slag, Mountain Flour, Industrial Waste. |

| Usage | To Produce Hollow Block, Solid Brick, Porous Block, Paving Brick, Interlocking Brick and Paver Through Exchange the Mould |

| Pallet Size | 1020×570×30mm(Wood Pallet) 1020×570×20mm(PVC Pallet) |

| Hydraulic Pressure | 16MPA |

| Exciting Force | 380KN |

| Forming Cycle | 15 -20 Seconds |

| Vibration Type | Table Vibration |

| Power | 27.5kw |

| Vibration Frequency | 4600/min |

| Workers | 5 Persons |

| Land Area | 1000m² |

| Weight | 8600KG |

| Block Machine Size | 6800×16 |

Theoretical yield table of QT4-15 brick machine

| Brick Specifications | Samples | pcs/mold | pcs/h | pcs/8h | 1 year (300 days) |

| Blocks 390×190×190mm 71pcs/m3 |

|

4 | 720 | 5760 | 24338m3 |

| Blocks 390×100×190mm 135pcs/m3 |

|

8 | 1440 | 11520 | 25600m3 |

| Dutch Bricks 200×100×60mm 50pcs/m2 |

|

14 | 2520 | 20160 | 120960m2 |

| Dog-Bone Bricks 200×165×60mm 30pcs/m2 |

|

8 | 1440 | 11520 | 114059m2 |

| Zigzag Bricks 225×112.5×60mm 40pcs/m2 |

|

12 | 2160 | 17280 | 131241m2 |

| Perforated Bricks 240x115x90 402pcs/m3 |

|

12 | 2160 | 17280 | 5.18 million pcs |

| Solid Bricks 240x115x53 683pcs/m3 |

|

24 | 4320 | 34560 | 10.37 million pcs |

1) Classic vibration mode, particularly suitable for production of high-strength blocks, such as standard bricks. Short molding cycles, and higher efficiency.

1) Vibration machine for efficient vibrator, exciting force powerful, the density effect of better products.

2) Forming large area, can produce a variety of cement products, a wide range of production.

3) Compulsory mechanical positioning, infantry expected rapid, uniform and manufactures precision, consistency, good.

4) PLC automatic control systems, interactive user interface, the control system, security configuration logic control, production procedures and fault diagnosis display.

5) The low cost of production, raw materials, make full use of sand, stone powder, flour, coal ash, slag, and other residue.

1. Haomei factory covering 200,000㎡, 500 workers, 35 engineers, and 90 technicians.

2. HAOMEI provide full support on Installation&Training. We provide the block machine installation on customers’ local site. And promise to train the brick makers until customer can operate the brick machine expertly.

3. With independent right to export, HAOMEI is one of the first company in China to export the block making machine to overseas market. Until now, HAOMEI has exported to 106 countries and region all over the world.

4. Certificate: EU CE, ISO9001, ISO Quality Management System, ISO14001 Environmental Management System.

5. 50 technicians work overseas to do the service for our customers in different countries.